On 10 Jan 2025, our students participated in the "Visit to Calbee Hong Kong Plant," organized by the Economics and Business Society.

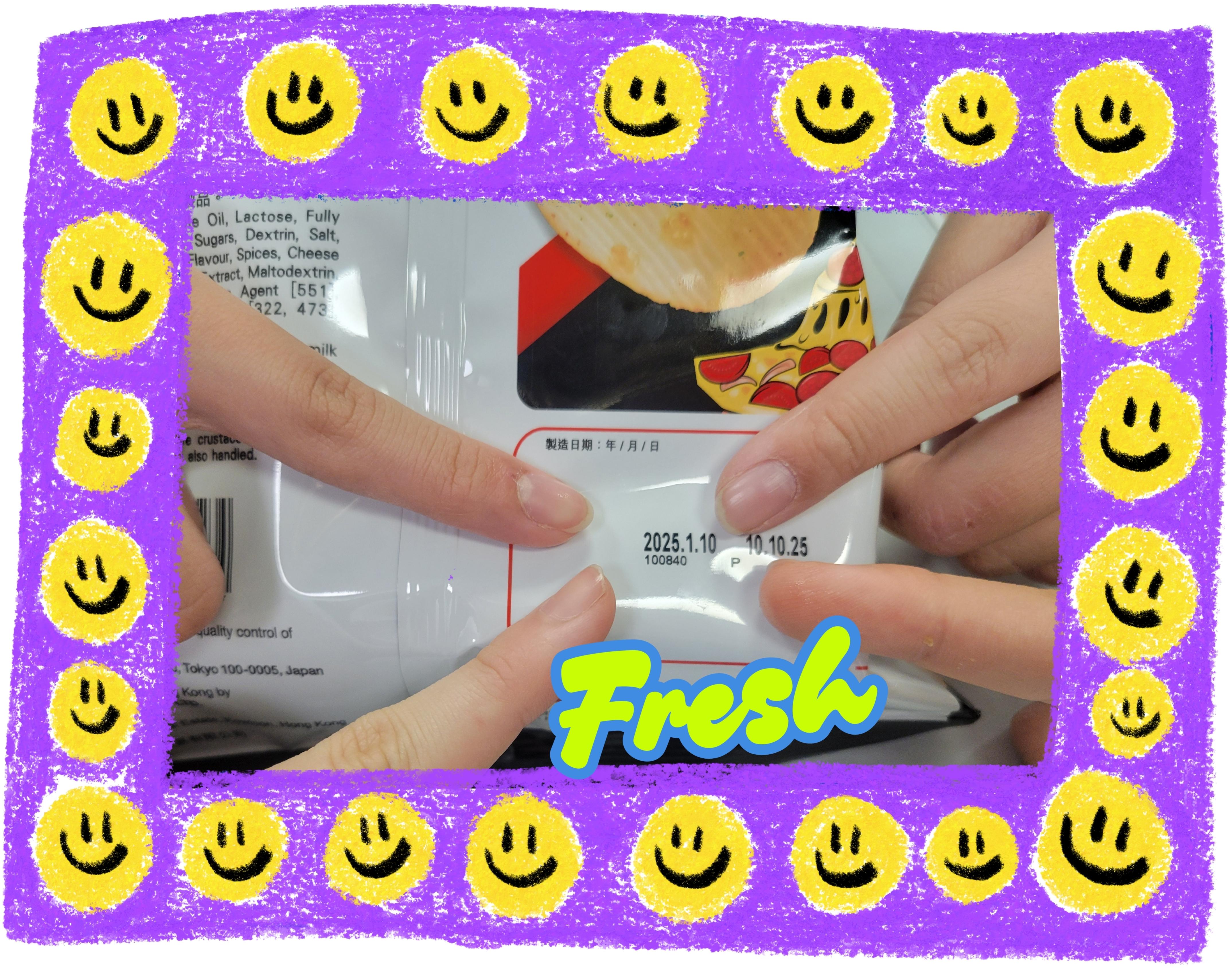

The visit commenced with a guided tour of the interior of the factory. Upon arrival at the facility, potatoes undergo a meticulous process including sorting, inspection, peeling, washing, frying, and seasoning. Each batch of potato chips must pass rigorous quality control checks to ensure the final product meets the highest standards of taste and quality. This experience underscored the importance of food quality and safety. The complexity of the production process revealed the significant effort and dedication behind each packet of potato chips, reminding us to value and appreciate the hard work involved.

Furthermore, the staff introduced us to the "potato storage warehouse." The warehouse maintains a dark environment with a temperature range of 15-17 degrees Celsius, simulating the natural underground conditions where potatoes grow. This temperature control helps preserve the freshness of the potatoes, demonstrating how technology can be effectively used to maintain food quality. Despite the warehouse being filled with potatoes, the supply can only sustain the factory's operations for approximately one week. Interestingly, producing a single 55g packet of potato chips requires three to four potatoes sourced from various regions worldwide, an eye-opening fact that deepened our understanding of the manufacturing process.

Overall, this visit was both engaging and highly informative, offering us a more comprehensive understanding of snack production and factory operations.

(Written by 5C He Yu Shan, 5C Chan Wing Ying)